Promac Skid-steer Attachments

Promac has the right skid-steer attachment for every application.

Promac’s revolutionary, production-grade skid steer brush cutters and mulchers are custom-made in their full-service manufacturing facility in British Columbia, and shipped worldwide. Whatever the size or scope of your job, they have a wide variety of equipment that will help you get it done safely, quickly and efficiently. Plus they have the technology, parts and know-how to keep your equipment running.

Brush Mulcher Series

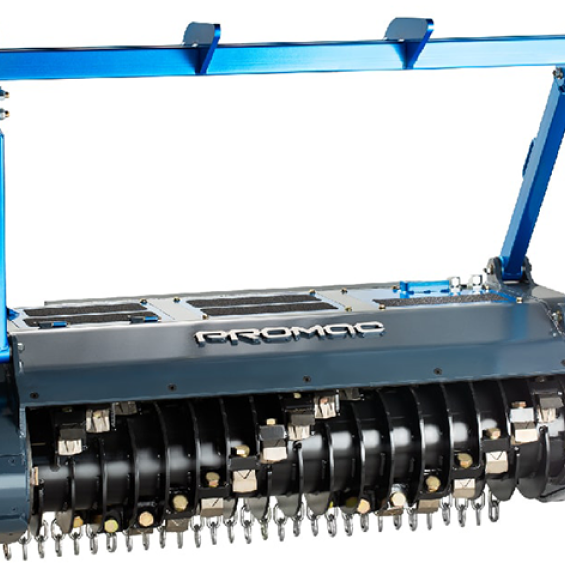

Promac HSM 60 Heavy Duty Skid-Steer Mulcher

Class-leading quality and features for serious mulching.

- Heavy-duty, low profile frame design incorporates high-strength steel, full-strength welds, and smooth lines for durability, visibility, and no material hang up.

- Easily replaceable wear parts ensure longevity and low cost of ownership.

- Powerful and efficient variable torque piston motor.

- Equipped with Promac’s proven next generation Chip Production Rotor (CPR) that offers 60” of cutting width at just 2,500 lbs.

- Suitable for a high-flow skid steer.

Promac HSL 60 Light Skid-Steer Mulcher

Adaptable skid-steer or excavator mounted mulcher.

- Heavy-duty, low-profile frame incorporates high-strength steel, full-strength welds for durability.

- The boxed-in design provides better rigidity and maneuverability for smaller skid steers.

- Easily replaceable wear parts ensure longevity and low cost of ownership.

- Powerful and efficient variable torque piston motor.

- Equipped with Promac’s proven next generation Chip Production Rotor (CPR) that offers 60" of cutting width at just 2200 lbs.

- Suitable for a standard flow skid steer.

Brush Cutter Series

Promac TDM 72 Twin Disk Skid-Steer Mulcher

- A result of extensive development, customer consultation, and rigorous testing.

- Combines technology found in Promac's other mulchers and takes them to the next level.

- Powered by two radial piston motors, requiring 36 GPM @ 4000psi.

- Produces high torque even at low RPMs where standard hydraulic motors stop producing.

- Two counter rotating discs.

- Three counter anvils.

- Economical tooling.